Our own solutions for total control

Our own microelectronics as part of a system for digital control and optimisation of waste disposal

Production and integration of electronics

The company has always focused on a comprehensive approach to solving automation problems. Therefore, the company's own design and development department of equipment and digital devices has been successfully functioning for a long time. Engineers and installers develop and constantly improve devices that are an integral part of the software produced by the company.

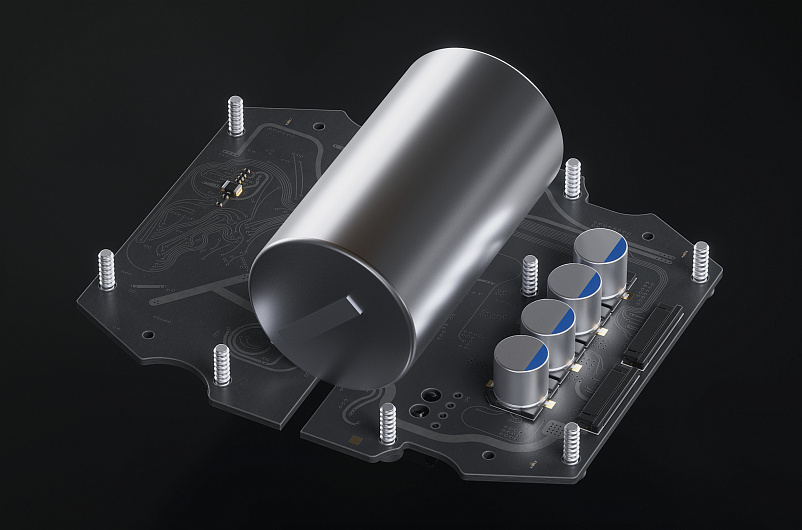

B3-SWFS container filling sensor

The sensor is designed to register changes in the level of filling of containers. In addition, the sensor allows to monitor changes in the angle of rotation of its body. The accumulated data is transmitted to a dedicated data collection device, from which it can be received via the Internet for further analysis and processing by software.

Device features:

- The only solution on the market - the flange is attached to both the container lid and the wall.

- Refined body with new optical module with integrated camera for photofixation.

- 2 sensitive rangefinders.

- NB-IoT or 3G.

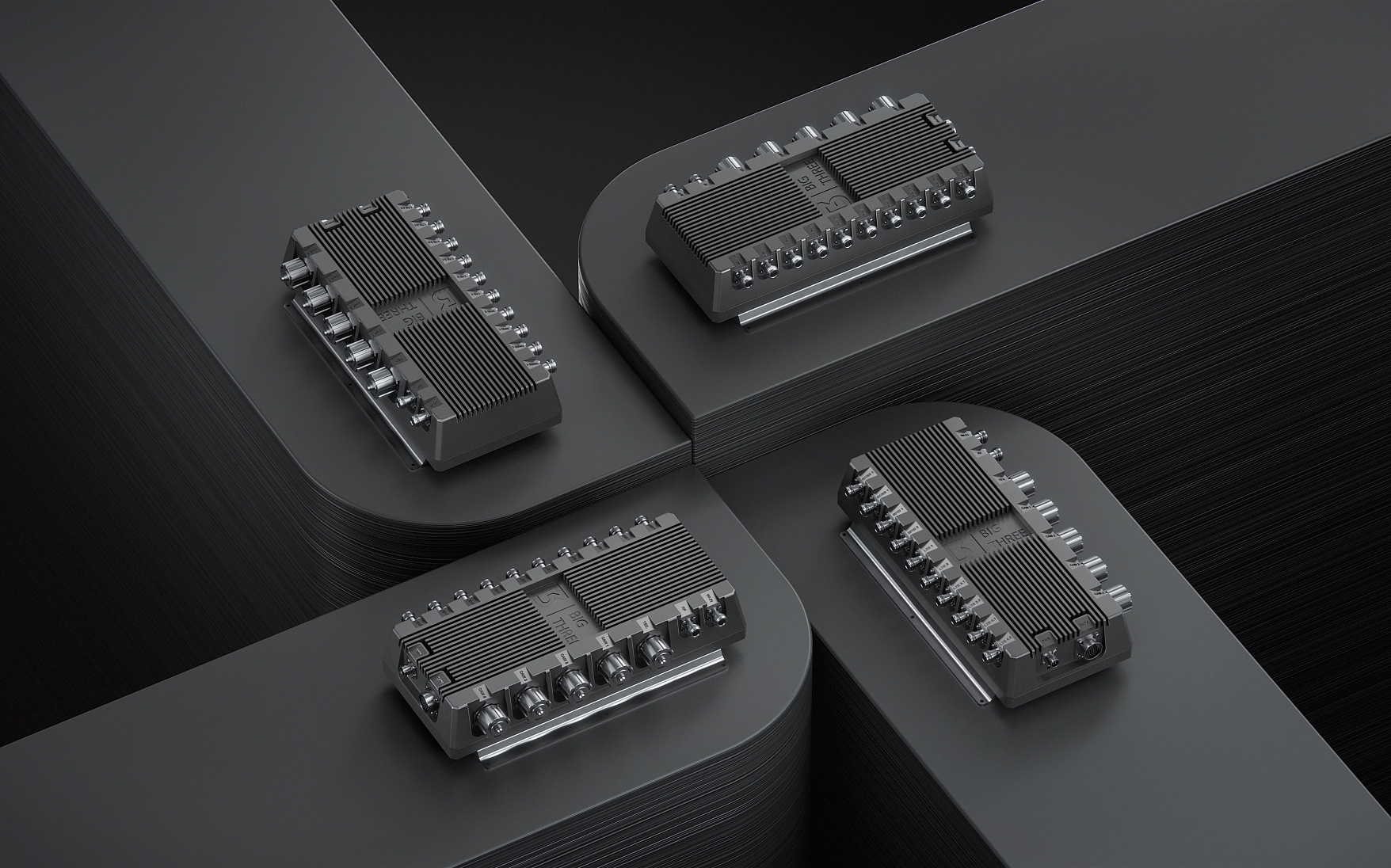

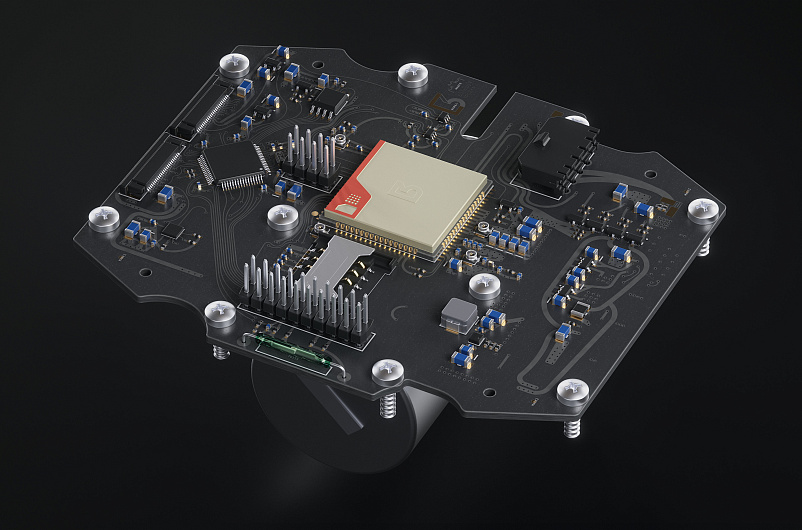

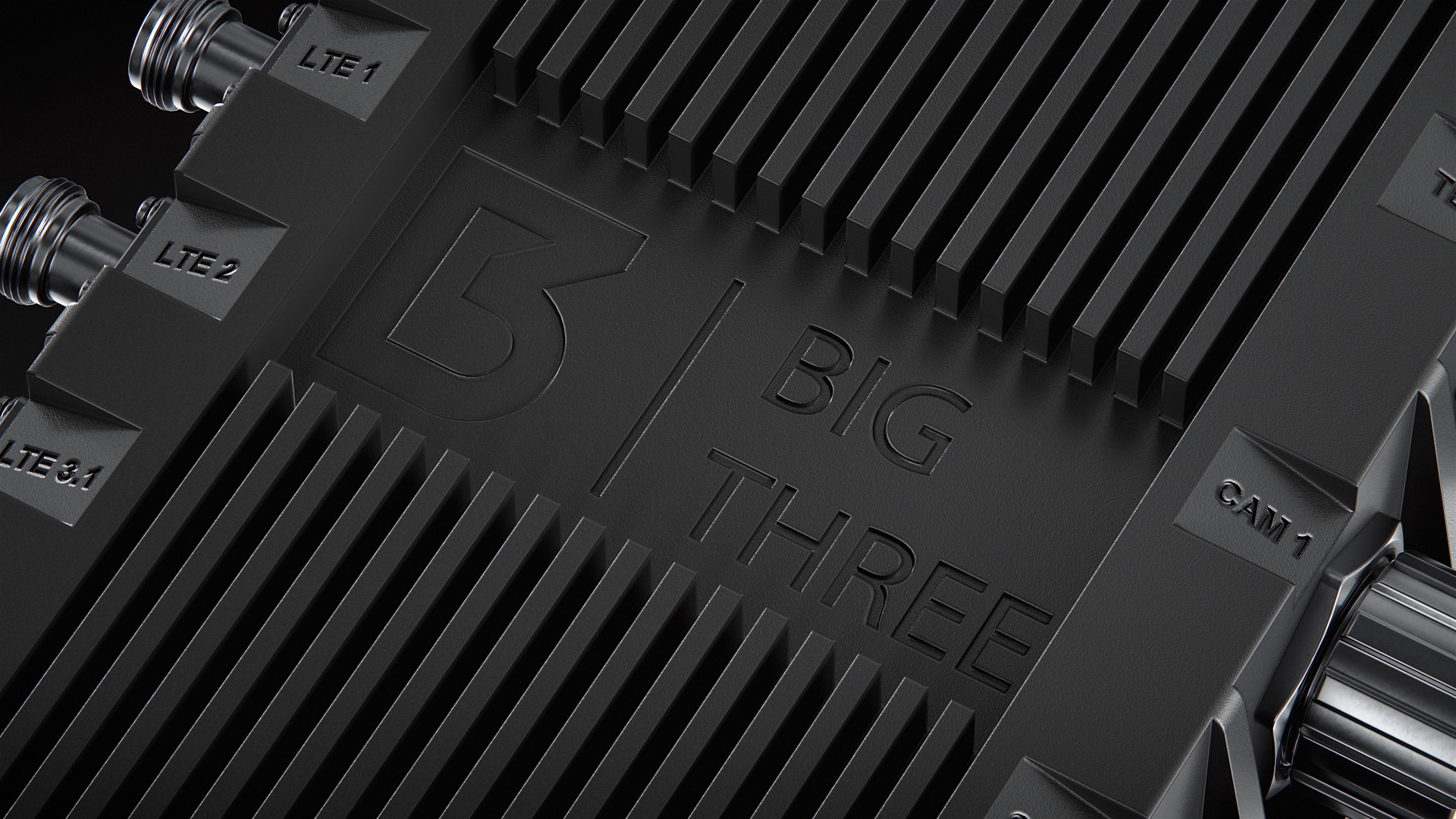

SOC controller (objective control system)

«The Big Three» has developed its own solution for converting payments from standard to actual.

In essence, the controller is the brain of the system. The device is equipped with RS-485 ports and has its own radio bus for connecting external devices, such as RFID tag readers, vehicle attachments (pressure and temperature sensors, external pressure sensors for attachments, and much more). The controller, together with cameras, rfid-reader and other attachments are installed on the waste truck. The controller uses its own neural network developed by The Big Three.

«The Big Three» has developed its own solution for converting payments from standard to actual. In essence, the controller is the brain of the system. The device is equipped with RS-485 ports and has its own radio bus for connecting external devices, such as RFID tag readers, vehicle attachments (pressure and temperature sensors, external pressure sensors for attachments, and much more). The controller, together with cameras, rfid-reader and other attachments are installed on the waste truck. The controller uses its own neural network developed by The Big Three.

Recognising different types of waste in a container

The photo is the results of a trained ultra-accurate scalable neural network based on selected 19 classes representing different types of waste that are thrown into containers. The selected classes are correlated with the main visual features of the most common subtypes of waste, which can be clearly distinguished using a camera installed on the truck. Despite the low resolution of the camera and the relatively small size of the identified class instances, it is possible to visually interpret the occupancy of a particular container whose contents are loaded into the truck.

Determining whether a container is available on the site, the volume of the container to be picked up and its overflow

The Big Three has incorporated a neural network into its products - the very same neural network that, in a sense, is a brain imitator with the ability to learn and orientate itself in conditions of uncertainty, such as a waste container site. Our neural network is able to identify the actual presence of a container on the site, the compliance of each particular one of them with the given one in the disposal plan and even determine the volume of filling or overfilling of the tank.